Material & Surface Profilometry

Tactile and optical measurement with micro- & nanometer resolution

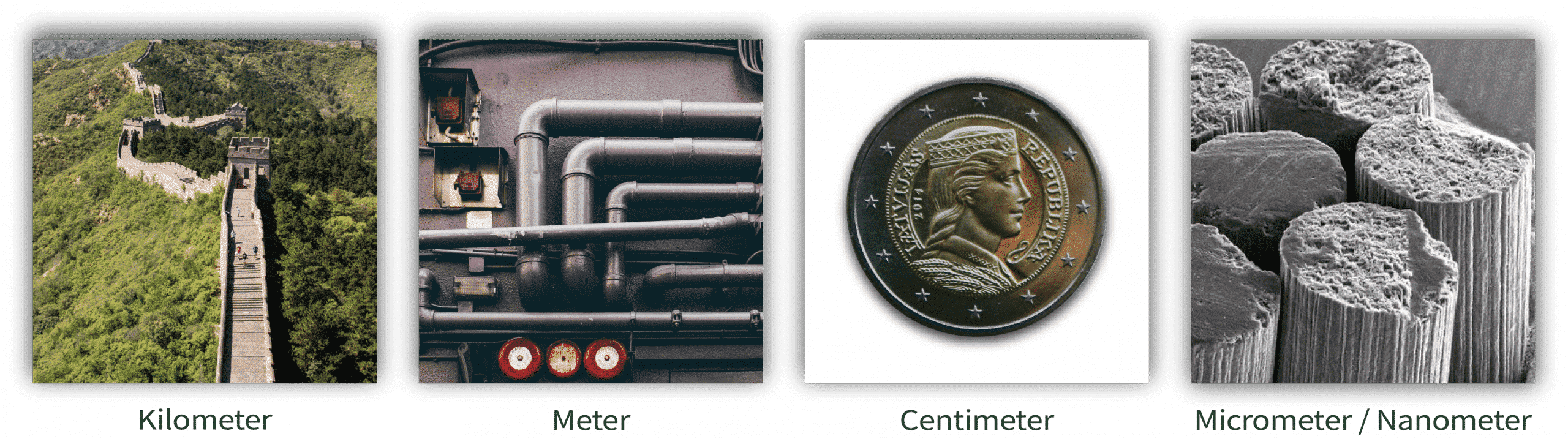

Topography is a study of structure and features of the material surface. It ranges in macro, micro and nanometers. Topography covers the three-dimensional structure of the surface, and the identification of specific profile.

Topography has been applied to different application fields. For example, in neuroscience, or neuro-imaging, they use topography for brain mapping. In ophthalmology, they use topography for mapping the surface curvature of the cornea. In material science, they use topography to indicate the patterns of the surface structure and pattern in which various values (or their values) are distributed in 3D, and those values are often referred to as roughness Ra, Rq and Rz.

Micro-topography of material surface becomes an increasingly important parameter for defining surface properties, machining process quality and functional correlation to the others. It is a key parameter of a product’s quality, which affects the product’s overall performance. The height values (oftenly refers to the valleys and peaks) of the surface determines many functional features, eg. abrasion resistance, adhesion, etc. Furthermore, the analysis of wear or abrasion rate after the mechanical tests is also needed to evaluate the quality of surface coatings. Therefore, an accurate measurement and documentation of the surface profile helps to make the right decision for the quality control.

Parameters which can be measured include:

• Roughness

• 3D Topography/Mapping

• Macro & micro geometries

• Light intensity

• Porosity

• Effective contact area ratio

The following technical equipment can be used for topography characterizations:

- UST®-Universal Surface Tester

- Traceit®

- White-light interferometer with height measurement range of 100 µm (surface roughness characteristics according to DIN EN ISO 25178)

- Confocal laser scanner (SurfScan)

- Tactile roughness measuring instrument (profilometer, roughness parameters according to DIN EN ISO 4287)

- Atomic force microscope (AFM)

Contact us

- phone: +49 931 4104 884

- mail: info@i-spa.institute

-

Friedrich-Bergius-Ring 22

97076 Würzburg